Brake is related to traffic safety components. If not timely replacement of brake pads, it would be easy to directly damage the brake disc, and brake safety coefficient decreased, affecting the traffic safety. So how to judge the brake pads must be replaced? Generally the wheel brakes of less than three mm, rear brake pads must be replaced when less than two mm. Even if the brake pad thickness is commonly higher than the standard, best every 40000 kilometers on the replacement brake lining. Because in the event of damage the brake disc, brake disc replacement costs can be much higher than the brake pads. So how to buy brake pads?

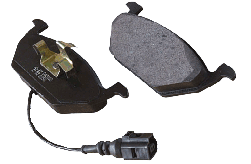

First of all, introduce the basic principle of the brake. When the driver depresses the brake pedal, the brake booster pump starts to work, the vacuum brake booster pump and hydraulic assistance through the brake fluid to pedal force amplifying and transfer to the brake caliper, caliper piston therefore push the brake wallet tight brake disc, friction between them by converting kinetic energy into heat energy of steam car, thereby to stop the car brake, the role of. Thus, the brake sheet is the direct component to achieve the brake, the friction friction material capability is very important. Brake general factory from the cost and the common use of perspective, the friction material on the braking effect is just enough. If you often high-speed driving, so the original factory brake is certainly not enough to use, the truth only two: one is the coefficient of friction is not high, the two is easy to produce thermal recession and ablation for friction materials. Brake how we choose the better from the two points are considered.

The friction coefficient is very important, friction materials of brake (attached to the metal on the floor of the grey black material) made of carbon, wear-resistant metal and other materials by high temperature high pressure and into (brake pads within the metal content the higher the more resistant to high temperature, but also more suitable for performance car use, but also on the brake disc wear also the greater), the friction coefficient has high anti high temperature and anti shear ability. It is well known that a certain area (brake pad area unchanged), the friction coefficient and the friction surface of the friction material size and positive pressure (brake calliper piston thrust) is proportional to, so when a certain degree of positive pressure, the friction coefficient is big braking effect is better. This is also an important way of modified brake pads.